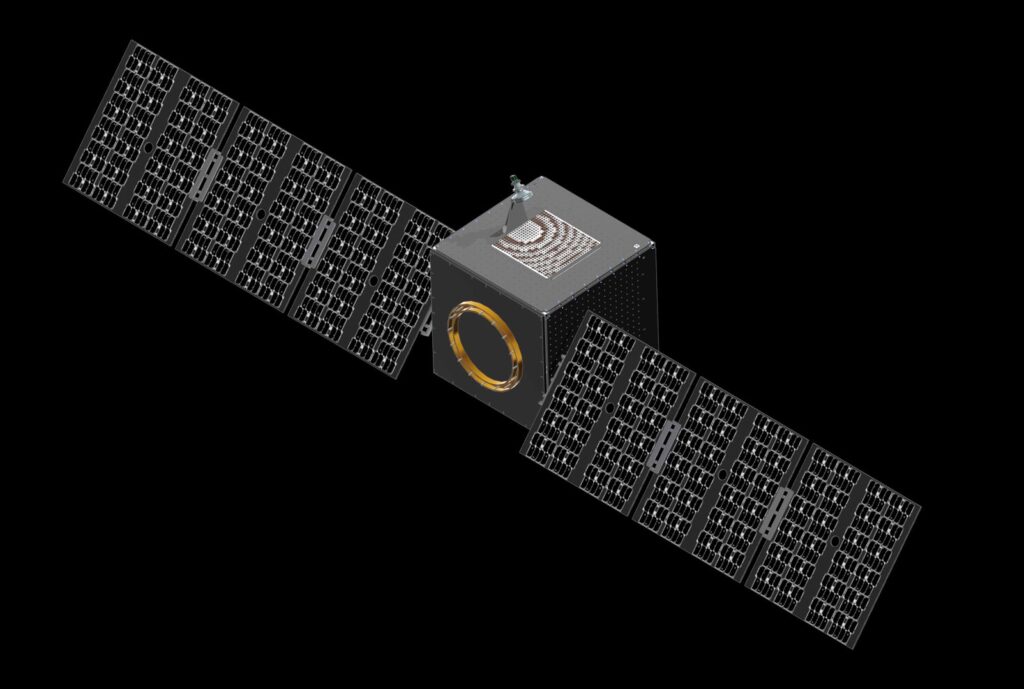

OrbAstro has made available the world’s most capable 400kg-class satellite platform, that is delivered on a lead-time and at a price-point that is simply unmatched.

£837,000

+£8,500/kg (TBC) for launch

Included in this price: the satellite platform, engineering support with payload integration, flight-acceptance testing of the fully integrated satellite, and storage before shipment to the launch provider, and in-orbit commissioning. Launch can be managed by OrbAstro and provided through a 3rd-party partner; price displayed is indicative of standard LEO/SSO orbit. Spectrum filing and launch license can be managed by OrbAstro on a case-by-case basis.

This product-line has been made possible through contracts with:

|

Spec |

Baseline Option |

Upgrade Options |

|

OBC |

Telos-40 |

Additional Telos-10, Telos-40, Telos-45, Telos-60 |

|

EPS |

280Wh (2x 140Wh) |

570Wh, 860Wh, 1440Wh |

|

Comms |

S-band transceiver + antenna (5Mbps), optical transceiver (Guardian Network), low data-rate S-band omni-directional. |

Additional X-band transmitter with 22/29dBi reflect-array antenna, Ka-band transmitter with 33dBi reflect-array antenna |

|

ADCS |

0.1º pointing accuracy, 0.01º knowledge, dual star-trackers |

Higher pointing accuracy available on request |

|

Propulsion |

— |

Nova-W, Electric Arc Jet |

|

Solar Panels |

Chassis mounted, 230W |

Deployable panels (static or articulated), up to 1.3kW |

|

Redundancy |

Fully dual-redundant OBC, EPS, ADCS, RF systems |

— |

|

Lifetime |

8-10 years |

— |

|

Spec |

Description |

|

Volume |

Standard: ~867U (1010 x 1010 x 850mm) Chassis Extended Option 1 (150cm): ~1326U (1010 x 1010 x 1300mm) Chassis Extended Option 2 (200cm): ~1836U (1010 x 1010 x 1800mm) |

|

Mass |

Standard: Up to 355.2kg (satellite maxi-mass 400kg, satellite platform mass 44.8kg) Chassis Extended Option 1 (150cm): Up to ~440.5kg (satellite maxi-mass 500kg, satellite platform mass ~59.5kg) Chassis Extended Option 2 (200cm): Up to ~430kg (satellite maxi-mass 500kg, satellite platform mass ~70kg) |

|

Power |

Maximum power consumption 1.6kW, upgradeable to 16.5kW with upgraded EPS. |

|

Data Interfaces |

I2C: 2x interfaces @10, 100, 400, 1000 kHz SPI: 1x interfaces @1, 10, 40 MHz USART: 2x interfaces, up to 1 Mb/s CAN: 2x interfaces, up to 1 Mb/s LVDS: 10 pairs, up to 1.2 Gbps per pair PCIe 3.0, up to x4 USB 2.0 Ethernet 10/100/1000Mbps |

-

- You place a 2% deposit per satellite to secure yourself in the production queue and at the “early adopter rate”.

- You hire a flat-sat to design/program your payload for compatibility with the platform.

- Once ready, you pull the trigger for satellite platform build.

- Once the platform is built (nominally 3 month later), you come on-site and integrate your payload with assistance from our engineers. This should not take more than a week because of your upfront work on the flat-sat.

- Whilst you are on-site, we put the fully integrated satellite through fight-acceptance testing. This should not take more than a week after your payload has been integrated.

- After passing flight-acceptance testing and further health-checks, the satellite is securely stored on-site in an appropriate environment until the launch provider is ready to receive it.

- You organise shipment of the satellite from OrbAstro to your designated launch provider, we support with export paperwork.

- We support integration of satellite with launch vehicle.

- We commission satellite platform once dispensed in-orbit, and support you with payload commissioning.

- You carry out mission operations through our highly automated and user-friendly Mission Control System and receive on-going technical support from us.

-

-

£837,000 baseline

The price includes:

-

-

- A fully assembled satellite platform

- Engineering support with payload integration, on-site with us

- Full flight-acceptance testing and associated health-checks, on-site with us

- Packaging for transportation

- Storage of the satellite until the launch provider is ready to receive it

- Support with integration of satellite to dispenser/launch vehicle

- Satellite in-orbit commissioning

-

Nominal lead-time for production of ORB-100 satellite platforms is 3 month.

Fees associated with management/support of on-going satellite operations discussed on a case-by-case basis.

-

-

-

Deposits are 2% of baseline price of satellite.

|

Upgrade/Additions |

Description |

|

Launch +£8,500/kg (TBC) |

OrbAstro management of launch through a 3rd-party partner. Price dependent on launch provider and orbit selected. Includes launch, ejector ring, and management. |

|

Spectrum Filing & Launch License +£38,000 (TBC) |

OrbAstro can manage the acquisition or relevant paperwork associated with launching and operating the satellite. Price is dependent on the unique customer requirements. |

|

OBCs Telos-10, +£5,100 |

Additional OrbAstro Telos-class OBCs can be added to the platform for various applications. Each additional OBC will reduce payload volume by ~0.1U. |

|

Battery 560W EPS, +£26,500 |

To increase power storage capacity of the platform, the battery can be scaled up. This will reduce payload volume capacity respectively. |

|

Fixed Deployable Solar Panels 1-wing-1-panel, +£97,000 |

Power available to the payload can be increased in increments with the addition of deployable solar panels. From a baseline of typically 33Wh orbital average available for the payload up to 1,025Wh. This will not impact payload volume capacity. |

|

1 DOF Functional Deployable Solar Panels 1-wing-1-panel, +£182,250 |

Power available to the payload can be increased in increments with the addition of deployable solar panels. From a baseline of typically 33Wh orbital average available for the payload up to 1,025Wh. Adding a degree of rotational freedom enable more mission flexibility. This will reduce payload volume capacity respectively. |

|

High-Speed Downlink X-band transmitter with 22dBi antenna, +£40,250 X-band transmitter with 29dBi antenna, +£51,750 Ka-band transmitter with 33dB antenna, +£55,250 |

To increase down-link capabilities, an OrbAstro Ka-band transmitter can be added with a reflect-array antenna. This will compliment the S-band transceiver. |

|

Additional Onboard Storage 128GB, +£3,000 |

Increasing capacity of onboard storage extends what is achievable and flexibility of a mission. |

|

Electrical Interfaces First two electrical interfaces included in baseline price, additional interfaces incur +£2,500 per interface. |

I/F Options: – I2C: 2x interfaces @10, 100, 400, 1000kHz – SPI: 1x interfaces @1, 10, 40MHz – RS422: 2x interfaces @10Mbps – RS485: 2x interfaces @10Mbps – UART: 2x interfaces (up to 1Mb/s) – CAN: 2x interfaces (up to 1Mb/s) |

|

High-Speed Electrical Interfaces Each interfaces incurs +£2,500 Requires at least a Telos-10 OBC to compliment. |

I/F Options: – LVDS: 1x interface, up to 10 interfaces (up to 1.2 Gbps per pair) – PCIe 3.0, up to 4 lanes – USB 2.0 – Ethernet (10/100/1000Mbps) |

|

Chassis Extension Extend Chassis length to: |

Sometimes a payload will not be compatible with our baseline chassis. Instead of modifying the payload to conform, it may make more sense to modify the chassis. This chassis extension also increases the satellite maxi-mass to 500kg, respectively increasing. payload maximum mass to 440.5kg (150cm variant) and 430kg (200cm variant) |

|

Warranty +12% of total satellite price |

Replacement of satellite platform if there is a Constructive Total Loss of the mission between satellite departure from OrbAstro premises and the completion of one year of in-orbit operations (terrestrial transportation, in-orbit commissioning, and one year of in-orbit operations). Note this does not include mission failure due to launch failure or failure of the Customer payload. |

All subsystems have been subjected to extensive testing, are flight qualified, and have flight heritage. The same subsystems are used across the entire ORB-class satellite platform range.

Subsystems

The volumetric efficiency of the ORB family of satellite platforms has been enabled by the team compressing what is typically seven 1U-scale PCBs into a single 80x75mm board. This “satellite on a board” contains: the OBC, reaction wheel controls, magnetorquer controls, camera interfaces, star-tracker interfaces, all sensor interfaces, full SDR S-/X-band, GPS, optical data processing and control, and EPS.

-

- The platform utilises an OrbAstro Telos-40 OBC.

- The OBC is based on Xilinx Ultrascale+ MPSoCs with ARM cortex A53 and R5 64-bit processing cores, 2GB LPDDR4, 64GB eMMC, 250GFLOP double precision FPU, software and hardware based mitigation for SEU and SEL.

- Hardware-level ECC for boot ROM.

- Additional customer-dedicated onboard computers can be provided for various applications.

-

- The platform hosts an optical communications system for data relay through the Guardian Network satellites. Subscription packages vary, but 500MB/day uplink/downlink with up to 24 links per day is the baseline. Service available from mid-2025.

- As a back-up, and until the Guardian Network satellites become operational, the platform contains an S-band transceiver and antenna with a 5Mbps typical data rate at 1,000km for conventional ground link. All Guardian Network ground stations are capable of supporting S-band, X-band, and Ka-band links.

- The S-band transceiver can be complimented with a Ka-band transmitter and reflect-array antenna.

-

- The ADCS is based on an array of reaction wheels, magnetorquers, dual star-tracker cameras, Earth and Sun cameras, magnetometers, gyroscopes, and GPS unit, with a relatively comprehensive level of redundancy built in.

- It provides highly accurate pointing control authority (<0.1deg/s) and pointing knowledge (<0.01deg/s) in both Solar and Eclipse phases.

- High precision dual star-trackers heads for redundancy.

- Dual redundant 3-axis magnetorquers.

- It provides extremely high torque authority (78mNm) and momentum storage capacity (2.45Nms), typically an order of magnitude higher than what is conventionally available for 6U satellites. This ability for agile steering/pointing enables the customer to increase the amount of useful data collected by their payload (i.e. by jumping between points of interest through the orbit rather than say maintaining a fixed NADIR-pointing angle). The overhead for this type of target-tracking operation is much compressed when coupled to the Guardian Network autonomous mission operations service.

-

- The platform will utilise a 280Wh variant of the OrbAstro EPS technology.

- There are optional upgrades available, to increase power capacity of the battery to 560Wh, 860Wh or 1,440Wh.

- Utilisation of conventional lithium-ion chemistries for batteries are one of the primary causes of early decommissioning of nanosatellites, due to cycle lifetime and vulnerability to the thermal environment.

- OrbAstro uses an alternative cell chemistry far better suited to the LEO environment and satellite mission requirements.

- The battery can operate at an 85% depth of discharge over a period of 30,000 cycles at 2C.

- Maximum power consumption 1.6kW (upgradeable to 16.5kW with upgraded EPS).

- The battery is extremely robust to the thermal environment, with an operating temperature range of -200C to +600C with minimal impact on capacity and lifetime.

-

- As a baseline, platform mounted solar panels are provided, generating 230W.

- Deployable solar panels (static or articulated) can be provided to increase power available up to 1.3kW.

Place a Deposit

To secure yourself in the production queue, and to freeze your platform price to the current rate, place your deposit now.

If you have any questions, send them in an email to:

FAQ

OrbAstro has built every subsystem on this platform from scratch and in unison. This provides significant mass, volume, power, and assembly process optimisation advantages not possible otherwise. And it compresses the supply chain significantly (i.e. fewer margins-upon-margins). A lean batch-production philosophy has also been adopted. We do not provide customers with a custom-built solution that involves months of negotiations over requirements and shopping around with suppliers. What we offer is a standard platform which as a baseline is massive overkill in most cases, from a performance requirements perspective. This allows us to addresses 95%+ of the nanosatellite/smallsat market without significant modification.

Rather than procuring independently developed subsystems, and attempting to bolt them together, OrbAstro has built everything as an integrated system from the ground up, from every subsystem to every line of flight-code, allowing for huge savings in volume consumed.

The company recently transitioned from R&D to commercialisation. All subsystems are flight-qualified and have flight heritage. With launches in 2022 and more than a dozen launches scheduled in 2023, significant heritage and flight data is being accumulated quickly.

Vibration testing. Sequence: LLS HLS, LLS, RV, LLS. Functional/health checks are carried out at every step. TVAC, EMC, and Shock testing can be provided as required, but as a baseline, this is not typically required for nanosatellites.

If the failure is on the platform side, either the defunct subsystem or the entire platform will be swapped out for a back-up free of charge (along with payload integration, and another round of flight-acceptance testing). If the failure is on the payload side, you will either need to make a quick fix on-site or take your payload home and come back with a suitably modified system when ready. In either case you will be charged an additional £75,000 to repeat the satellite rebuild, payload integration and flight-acceptance activities.

Yes. If you do not, there is a high likelihood that there will be numerous bugs that will take weeks to resolve when it comes to payload integration to the actual satellite platform. It works out more cost-effective for both us and you, to do all of that on the flat-sat before you come on-site.

No. You will get those subsystems anyway. In exceptional circumstances, it will be possible to remove some components if it is critical for the operations of your payload (e.g. removal of solar cells for line-of-sight or deployable structures). This approach minimises non-recurring expenses for us associated with handling, assembly, testing, and paperwork. Also, most subsystems onboard are required for connectivity with the Guardian Network, which will be a baseline part of the service package when it comes online.

We have three Guardian Network ground stations with more coming online. You will be able to access your satellite through these ground stations through either S-/X-/Ka-band, before the Guardian Network provides you with persistent access. We can assist or lead associated spectrum filings.